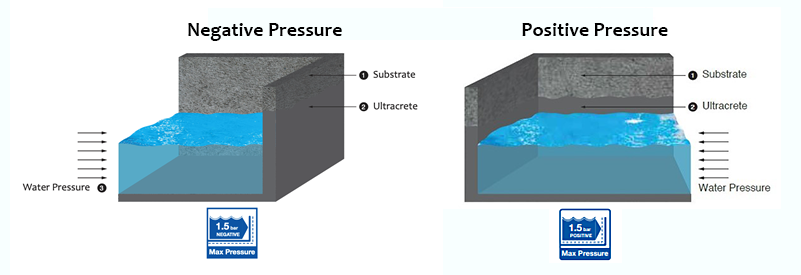

Ultracrete is a two component, flexible, positive-negative pressure waterproofer

Ultracrete is a two component, positive-negative pressure waterproofer which combines the flexibility and adhesion of high performance positive pressure waterproofers with the functionality of a negative pressure grade.

This combination greatly simplifies negative pressure waterproofing. Ultracrete also provides a film which has excellent durability combining superior tensile strength with low temperature crack bridging capability.

Ultracrete has the following properties:

Ultracrete is suitable for waterproofing masonry substrates in the following areas:

Preparation of surface:

For Positive pressure resistance (water exerts pressure directly onto the coating),

Ensure substrates are clean and sound. Remove all existing coatings, cement laitance, unsound honeycombing and spalling concrete by suitable mechanical means. All dust, dirt and loose materials must be thoroughly removed by brush, broom or vacuum from the areas to be coated.

Grind off all ridges and sharp projections. Scrape off all flaking material and remove oils, grease and other adhesion inhibiting substances. Mortar joints must be sound and finished flush with the blockwork.

In situations requiring reinforcement and at all wall and floor corner junctions, pipe entries and drains, it is recommended to apply the respective Terratape reinforcing membrane or Terraco Flexitape or Terraco Sealing Tape, depending on area of application.

Cracks and surface defects must be made good using suitable Terraco repair products.

Create a fillet in the corners where required, prior to application of Ultracrete.

In the presence of water which continuously seeps through, seal off the flow using Terraco Pluggit 311 and then continue as described above.

Dry and porous substrates should be primed with Terrabond A (diluted 1:3 with clean water) or Terraco Waterproofing Primer (undiluted). Other surfaces should be saturated with water prior to application but no standing water should be present.

For Negative Pressure resistance, (water exerts pressure to opposite side of the coating) Ultracrete is applied over unprimed concrete surfaces.

Mixing:

It is recommended to mix full kits only.

Place the resin in a clean mixing vessel then slowly add the powder while mixing for at least 3 minutes with a slow speed mixer (200-600 rpm) until the mix is completely homogeneous and lump free.

Ensure the blade remains below the surface of the mixture to minimise the entrapment of air and that no powder remains unmixed on the sides and in the corners of the mixing vessel.

Leave to stand for at least 5 minutes to release any entrapped air. Mix again for 30 seconds before application. During application, ensure occasional stirring to keep the aggregates in suspension.

Note: Do not add water to adjust or re-temper the mix. For bulk mixing, mix only required kits of Ultracrete that can be used within its pot life.

Application:

Ultracrete can be applied using brush or broom and worked into the surface thoroughly. Apply onto the freshly prepared substrate in 2-3 coats, applying each coat at right angles to each other, to a total thickness of 1.5 to 2.0mm. Total consumption is 2.8 – 3.8kg/m2 (mixed Ultracrete).

It is recommended that the total application thickness be 1.5 mm under tiles and 2.0mm for exposed areas. Leave minimum 6 hours between coats for drying at 25ºC.

Mixed Ultracrete must be used within 1 hour of mixing (do not re-temper with additional water).

Clean tools and equipment with water immediately after use

Curing

Curing and drying times depend on ambient temperatures, atmospheric humidity and thickness of coating. Protect surfaces from wind and direct heat during application and curing. Do not apply in humid conditions >80%.

Ultracrete will be surface dry in less than 3 hours at 30°C. Allow first coat of Ultracrete to dry for a minimum of 6 hours before over-coating. Ultracrete should be left to cure for at least 7 days before water flood testing.

Tiling work should be commenced after minimum 3 days of Ultracrete application. Protect surfaces from wind and sources of direct heat during application and curing.

Limitations

Do not apply during rising temperatures to avoid the risk of outgassing resulting in pin-holing. Do not apply on bituminous coatings. For exterior areas, do not apply if rain is likely over the next 24 hours.

| Product Name | Code |

|---|---|

| Ultracrete | 68510 |

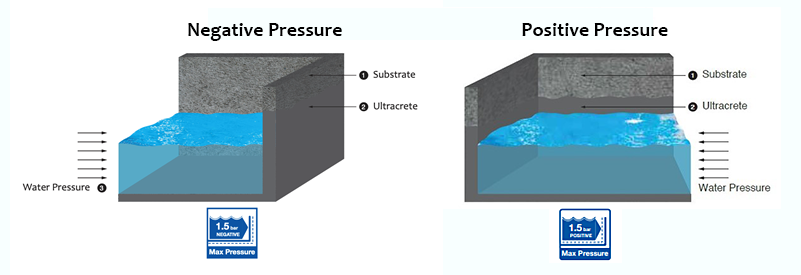

Ultracrete is a two component, flexible, positive-negative pressure waterproofer

Ultracrete is a two component, positive-negative pressure waterproofer which combines the flexibility and adhesion of high performance positive pressure waterproofers with the functionality of a negative pressure grade.

This combination greatly simplifies negative pressure waterproofing. Ultracrete also provides a film which has excellent durability combining superior tensile strength with low temperature crack bridging capability.

Ultracrete has the following properties:

Ultracrete is suitable for waterproofing masonry substrates in the following areas:

Preparation of surface:

For Positive pressure resistance (water exerts pressure directly onto the coating),

Ensure substrates are clean and sound. Remove all existing coatings, cement laitance, unsound honeycombing and spalling concrete by suitable mechanical means. All dust, dirt and loose materials must be thoroughly removed by brush, broom or vacuum from the areas to be coated.

Grind off all ridges and sharp projections. Scrape off all flaking material and remove oils, grease and other adhesion inhibiting substances. Mortar joints must be sound and finished flush with the blockwork.

In situations requiring reinforcement and at all wall and floor corner junctions, pipe entries and drains, it is recommended to apply the respective Terratape reinforcing membrane or Terraco Flexitape or Terraco Sealing Tape, depending on area of application.

Cracks and surface defects must be made good using suitable Terraco repair products.

Create a fillet in the corners where required, prior to application of Ultracrete.

In the presence of water which continuously seeps through, seal off the flow using Terraco Pluggit 311 and then continue as described above.

Dry and porous substrates should be primed with Terrabond A (diluted 1:3 with clean water) or Terraco Waterproofing Primer (undiluted). Other surfaces should be saturated with water prior to application but no standing water should be present.

For Negative Pressure resistance, (water exerts pressure to opposite side of the coating) Ultracrete is applied over unprimed concrete surfaces.

Mixing:

It is recommended to mix full kits only.

Place the resin in a clean mixing vessel then slowly add the powder while mixing for at least 3 minutes with a slow speed mixer (200-600 rpm) until the mix is completely homogeneous and lump free.

Ensure the blade remains below the surface of the mixture to minimise the entrapment of air and that no powder remains unmixed on the sides and in the corners of the mixing vessel.

Leave to stand for at least 5 minutes to release any entrapped air. Mix again for 30 seconds before application. During application, ensure occasional stirring to keep the aggregates in suspension.

Note: Do not add water to adjust or re-temper the mix. For bulk mixing, mix only required kits of Ultracrete that can be used within its pot life.

Application:

Ultracrete can be applied using brush or broom and worked into the surface thoroughly. Apply onto the freshly prepared substrate in 2-3 coats, applying each coat at right angles to each other, to a total thickness of 1.5 to 2.0mm. Total consumption is 2.8 – 3.8kg/m2 (mixed Ultracrete).

It is recommended that the total application thickness be 1.5 mm under tiles and 2.0mm for exposed areas. Leave minimum 6 hours between coats for drying at 25ºC.

Mixed Ultracrete must be used within 1 hour of mixing (do not re-temper with additional water).

Clean tools and equipment with water immediately after use

Curing

Curing and drying times depend on ambient temperatures, atmospheric humidity and thickness of coating. Protect surfaces from wind and direct heat during application and curing. Do not apply in humid conditions >80%.

Ultracrete will be surface dry in less than 3 hours at 30°C. Allow first coat of Ultracrete to dry for a minimum of 6 hours before over-coating. Ultracrete should be left to cure for at least 7 days before water flood testing.

Tiling work should be commenced after minimum 3 days of Ultracrete application. Protect surfaces from wind and sources of direct heat during application and curing.

Limitations

Do not apply during rising temperatures to avoid the risk of outgassing resulting in pin-holing. Do not apply on bituminous coatings. For exterior areas, do not apply if rain is likely over the next 24 hours.

| Product Name | Code |

|---|---|

| Ultracrete | 68510 |