The major causes of concrete decay in reinforced concrete is carbonation caused by Carbon Dioxide (CO₂) in the atmosphere reducing the alkalinity of concrete making it susceptible to attack by water and oxygen, causing corrosion of the steel and eventually spalling of the concrete. Sulphates from motor vehicle exhausts and chlorides from de-icing salts also contribute to concrete degradation.

Terraco Vapogard™ AC220 is a high performance anti-carbonation system which concentrates on using barrier coatings to protect concrete from the ingress of water and CO₂. Terraco’s system also understands that it is necessary for anti-carbonation coatings to be breathable which allows the free passage of moisture vapour, keeping the surfaces drier and free from the build-up of moisture which can enable diffusion of CO₂ and chlorides more easily into the concrete.

This 100% pure acrylic, waterbased, ultra-low VOC coating, is suitable for use on exterior and interior surfaces of concrete and anti-rust primed steel. Over and above protecting concrete from carbonation (anti-carbonation coating) the product provides outstanding protection to the substrate against UV rays.

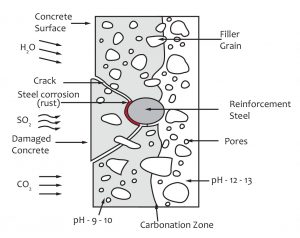

Causes of decay in concrete

Concrete has a high alkalinity, typically pH12 and pH13, which provides a protective passivation layer around the steel reinforcing bars, preventing corrosion. However, with the ingress of carbon dioxide over time if the concrete is not protected, it has the effect of reducing the alkalinity of the concrete to a pH of 9 and below leading to spalling concrete.

The main causes of concrete decay are:

Benefits

Areas of use

Vapogard AC220 can be used on new or old surfaces of concrete, brickwork, plasterwork, plywood, galvanised steel and anti-rust primed steel.

Suitable for:

VAPOGARD AC220 SYSTEM

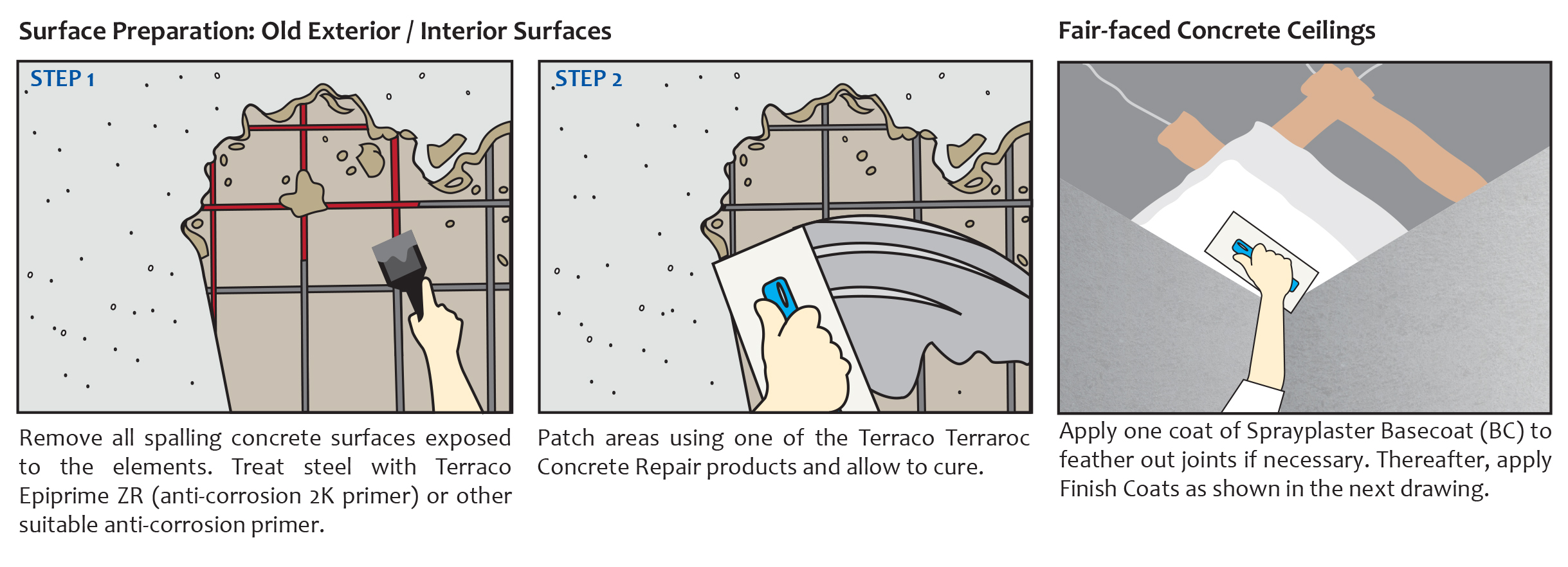

Surface Preparation: New Exterior / Interior Surfaces

Ensure that all dust dirt and foreign matter is scraped and brushed away. Ensure that all surfaces are free from salts, oil, grease and ridges. Repair all cracks, chips, voids and damages with:

Read more on the Terraroc Concrete Repair range.

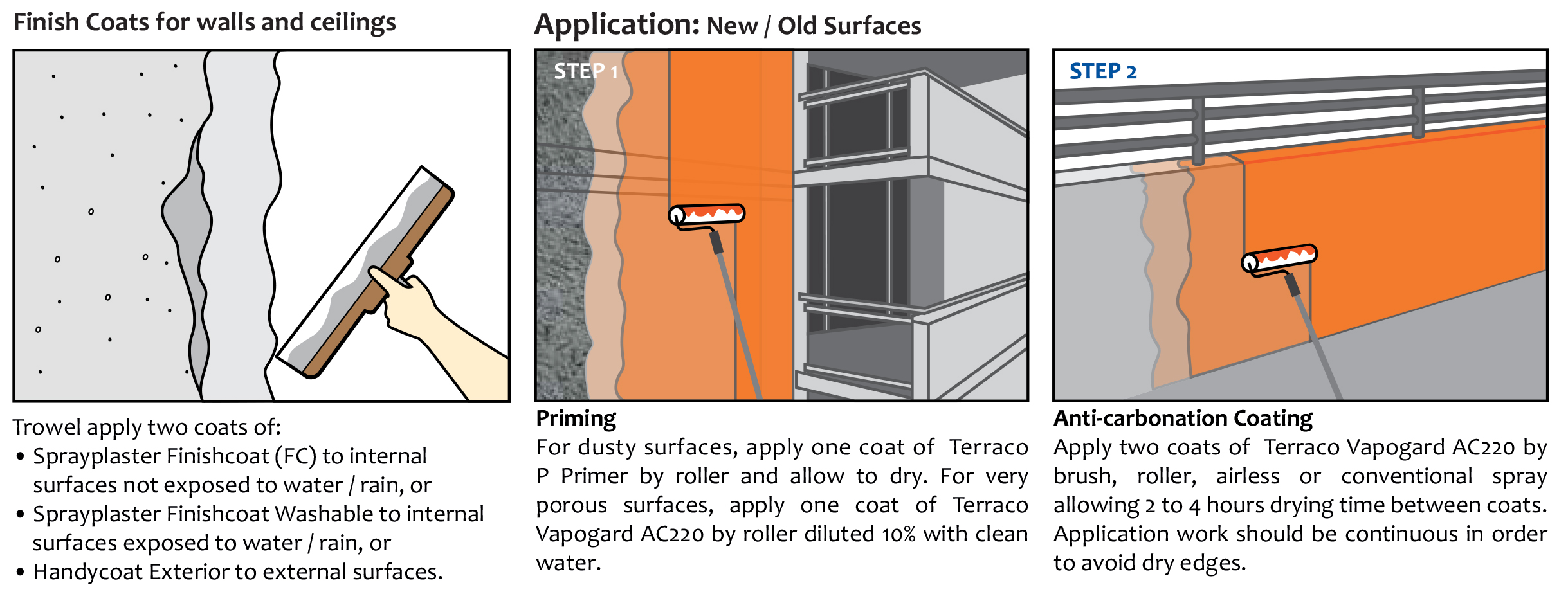

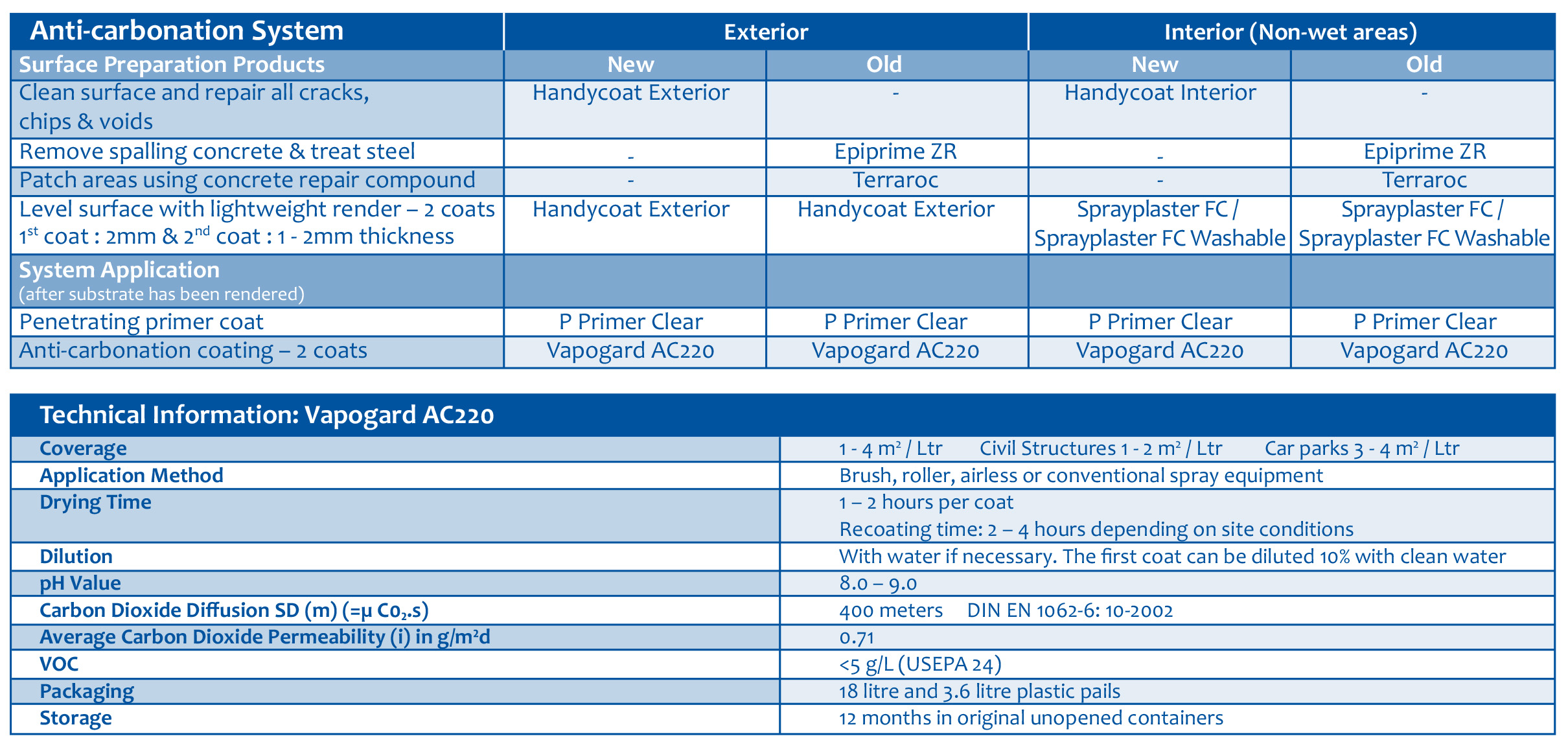

Quick Guide

These high performance anti-carbonation coating systems which use Vapogard AC220 as the finishing coat, provide long-term protection to concrete structures, both internally and externally.

Please contact your Terraco representative for further technical information.